Taynton History

Parish History

The Dobunni

Roman Iron Making

Roman mosaic

Taynton Parva

St Lawrence Church

Glass Making

Brick Yard & Pottery

Brass Mill

WWII

Typhoon Crash

Hampden Crash

US Camp

US Finds

Taynton Metal Detecting Club

The Gannets

Taynton Brass Mill

by Donald Sherratt.In the 11th century there was a corn mill called Abbelands Mill situated on the Huntley side of Taynton. It may have been the site of this or another corn mill that was taken over for making brass, a water wheel being needed to drive the huge bellows that provided a draught to the smelting furnace.

We do not know when the industry first started in Taynton but club finds and historical documents suggest the period of greatest activity appears to be from the late 16th century to the late 17th century. The Brass Mill was pulled down in 1706. Sometime in the 1960s the site was levelled but nevertheless the remains of an old leat are still visible. There are a few large stones in a gateway that were carried from the site. One is marked with a 111, another has a groove, probably part of a sluice.

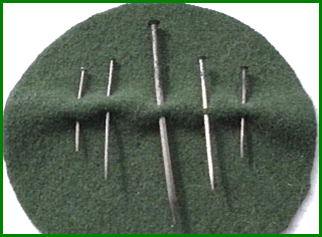

A document called the "Calendar of State Papers Domestic 1631- 1632 " states that "Tilsley the Gloucester pin maker was getting his Brass from Taynton". Pin-making began in Gloucester in the early 1600s and it eventually became a very important local industry employing hundreds of people. In 1627 the Gloucester Corporation loaned the sum of twenty pounds to Tilsley a pin-maker from Bristol "to furnish him with a house". He very soon set 30 boys to work and by 1630 he was employing 80 boys and 'wenches'. It became a very important industry employing hundreds of people. In the early days the drawing of the wire for making pins and the attachment of the heads was done by hand.

During 1996/97 David Hutton and I detected the site and found a number of artefacts which make it conclusive that brass making was taking place at the Brass Mills.

In a corner of a field called Lower Stoney Ground, which is adjacent to Brass Mill field on the opposite side of the mill stream, lumps of pure copper were found. Also a number of fire-clay crucibles were identified; these would have been used to contain the molten material in the furnace. A recent club dig turned up a fragment of fire clay crucible in Brass Mill field itself.

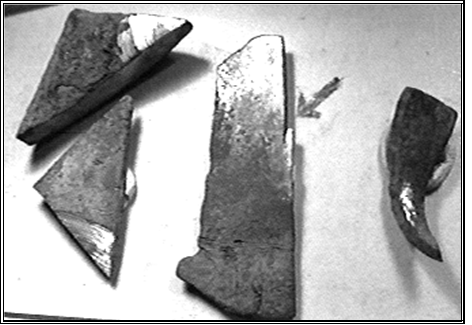

In the Brass Mill Field itself many lumps of brass were found including small pieces of flat brass sheet. One piece showed evidence that a thin strip of metal had been cut off it. Pieces of square section brass wire were also found.

A surprising discovery was a number of large Swedish 1 Ore coins of the reign of King Gustavus Adolphus dated 1629. These coins are made of copper and would have been brought in as scrap for melting down - one was found partly melted! Also found on the site was a heavy metal bar (probably part of a furnace) and a pair of pincers or tongs.

Brass is an alloy of copper and zinc and both these materials would have been obtained from afar. At that time pure zinc was not known; the zinc would have been in the form of calamine ore. Today in the Brass Mills field there are areas where little or no vegetation will grow due to the contamination of the soil by copper and zinc. The Forest of Dean provided a plentiful local supply of coal and charcoal.

Lumps of solid copper, brass and coal from the site.

The Copper would have had to be heated to over one thousand degrees Farenheit in a furnace using bellows to provide the draught - hence the need for a water wheel. It is believed that to make sheet brass in those days, the molten brass would have been run between two large flat stones with iron spacers between them and the width of the spacers would determine the thickness of the sheets. If necessary it could then be beaten out by the annealing process - i.e heating and hammering alternately. From the evidence that has been found so far, it appears that the main product manufactured there was thin brass strip that would have been supplied to the pin makers to be drawn out into wire.

There is no evidence remaining of the Mill building and we do not know where the Brass Mill House stood. In the corner of Lower Stoney Ground there is an overgrown enclosure of approximately half acre which is possibly the site, although there are no visible signs there today. The 1840 Tithe map of Taynton shows a pair of cottages lying mid-way between Lower Stoney Ground and Patches Meadow. These cottages could well have housed workers at the Brass Mill; a coin of Charles 1 dating between 1625 and 1649 was found at this location.

In the late 1600's brass-making began to become industrialised with large factories starting up in Bristol such as the Bristol Brass Company and the Warmley Brassworks. The Gloucester pin-makers were then able obtain cheaper and more regular supplies of brass leading to the decline of the small country mills such as the one at Taynton. Despite brass-making in Taynton coming to an end prior to 1700, pin-making became Gloucester's largest and most important industry. Pins were also produced in Newent by the inmates of the workhouse. Pin-making was also a cottage industry with people making pins in their own homes. In 1996 a considerable number of brass pins were found at the Old Forge, Taynton, under floor boards during renovation work.

Other finds from the Brass field indicating fifteenth and sixteenth century activity include part of a belt buckle that dates c1550 to 1650, a Tudor 2oz weight, part of a bracelet with face design, a C17th/C18th pewter button and a C17th brass button.